Thứ Năm, 28 tháng 9, 2017

Thứ Bảy, 23 tháng 9, 2017

Thứ Sáu, 11 tháng 8, 2017

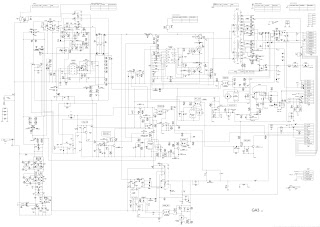

Orion TV29LB929 – 29 inch LCD/LED TV – how to enter service mode, adjustments, SMPS and backlight inverter schematic

Power supply and back-light inverter circuit diagram, service mode, Hotel mode, Reset, white balance adjustment – Orion TV29LB929 LED LCD TV - Used ICs in power and back-light inverter section circuit => MIP2M40MSSCF, FA5640N-C6-TE3, FMV09N90E(SMPS Switching FET), BD8779EFV-E2 (Backlight voltage control)

HOTEL MODE FUNCTIONTo set the Hotel mode, please follow the steps below.

1. Press the MENU ---> 1147 button on the remote control

2. Press the DOWN button on the remote control

3. Select the "Setup" menu , then press ENTER button

4. Select the "Hotel Mode" menu, Select "On".

5. The Hotel mode setting menu will appear

6. Using the UP/DOWN button on the remote control, select the desired mode. Then press the ENTER button.

7. Using the LEFT/RIGHT button on the remote control, set the mode to desired setting.

8. The Hotel mode has now been set up.

To reset the Hotel mode, follow the steps below.

1. Press the MENU => 1147 button on the remote control.

2. Press the DOWN button on the remote control,

3. Select the "Setup" menu , then press ENTER button.

4. Select the "Hotel Mode" menu, Select "On".

5. The Hotel mode setting menu will appear.

6. Press the DOWN button on the remote control,

7. Select the Clear Lock menu "Clear Lock" menu then press ENTER button , then press ENTER button.

8. The setting items has now been returned to initial value

1. Press the MENU => 1147 button on the remote control.

2. Press the DOWN button on the remote control,

3. Select the "Setup" menu , then press ENTER button.

4. Select the "Hotel Mode" menu, Select "On".

5. The Hotel mode setting menu will appear.

6. Press the DOWN button on the remote control,

7. Select the Clear Lock menu "Clear Lock" menu then press ENTER button , then press ENTER button.

8. The setting items has now been returned to initial value

CHECK FOR THE FIRMWARE VERSION

This unit is provided with the following SERVICE MODES so you can repair, examine and adjust easily

Do not adjust after other items except "Version Info".

1. Check of the VERSION and SUM DATA on the screen.

1 : Press the MENU è1147 button on the remote control.

2 : Press the DOWN button on the remote control,

3 : Select the "Setup" menu , then press ENTER button.

4 : Select the "Version Info" menu, then press ENTER button.

5 : On the screen as shown in Fig:

1. Check of the VERSION and SUM DATA on the screen.

1 : Press the MENU è1147 button on the remote control.

2 : Press the DOWN button on the remote control,

3 : Select the "Setup" menu , then press ENTER button.

4 : Select the "Version Info" menu, then press ENTER button.

5 : On the screen as shown in Fig:

ADJUSTMENT PROCEDURE

On-Screen Display Adjustment

1. Press the MENU => 1147 button on the remote control.

2. Press the DOWN button on the remote control

3. Select the "Video" menu, then press ENTER button on the remote control.

4. Select the "Color Temperature" menu , then press ENTER button on the remote control.

5. On the screen as shown in Fig:

PRINTED CIRCUIT BOARDS POWER (INSERTED PARTS)

SOLDER SIDE and POWER (CHIP MOUNTED PARTS)

SOLDER SIDE

SMPS and Back-light inverter board circuit diagram

WHITE BALANCE adjustments.

1. Place the set in Aging Test for more than 15 minutes.

1. Place the set in Aging Test for more than 15 minutes.

2. Please select input About mode to adjust W/B.

3. Receive the gray scale pattern from the Pattern Generator.

3. Receive the gray scale pattern from the Pattern Generator.

4. Press the INPUT SELECT button on the remote control to set to the AV mode

5. Using the remote control, set the brightness and contrast to normal position.

6. Press the MENU è1147 button on the remote control.

7. Press the DOWN button on the remote control.

8. Select the "Video" menu, and then press ENTER button on the remote control

ENTER button on the remote control ENTER button on the remote control.

10. Press the UP/DOWN button on the remote control to select the "R Gain", "G Gain", "B Gain", "R Offset", "G Offset", "B Offset

11. Adjust the LEFT/RIGHT button on the remote control to whiten the R Gain, G Gain, B Gain, R Offset, G Offset B Offset at each step tone sections equally..

12. Perform the above adjustments 10 and 11 until the white color is achieved.

Assemble a HiQ guitar amplifier - circuit diagram – using 6L6 and 12AX7 vacuum tubes

RCA’s first version of this tube was an early octal base tube. Like most with this base it had a metal, rather than glass, envelope. Later versions, including the 6L6G, 6L6GA, 6L6GB, 5881, 5932, 7027, and the final version 6L6GC had glass envelopes, which made radiation cooling of the anode easier. 5881 is next to the 6L6GB.

The 5881 should be ok with the plate voltages found in most guitar amplifiers designed for the 6L6GC but this is not guaranteed so you do risk blowing your 5881s if you put them in an amp designed for the 6L6GC.The valve 5581 can be replaced with 6L6 and the substitution for 12AX7 is ECC83

Valves don’t usually ‘fail’; they just get weaker and weaker. The actual age of the tube is not important. It’s how much it has been played. If you play your amp regularly and it’s been a year or more since you had a valve change, it’s almost certainly time to treat yourself to a new set of valves.

Don’t forget to buy “matched output pair” valves. This is really important. The matched valves have been carefully selected to be a close match both in gain and bias current. If you’re going to change amp valves always choose ‘matched quads’ if you have four output tubes or ‘matched pairs’ if you only have two.

If your guitar valve amplifier is not sounding quite so good as the day you bought it, change amp valves to restore that beautiful sweet tone. If it’s sounding a bit flat, thin and lacking in oomph, change amp valves on a regular basis if you want to keep your amp sounding its very best.

If you notice a loss in bottom-end and power, it’s most likely your power valves need replacing. If you’re getting strange sounds coming from your amplifier, first turn your gain section up, and slowly turn the master volume down.

If the noises continue after the master volume has been turned down, it’s most likely a power valve. If you turn the master volume down, and the noises disappear, it’s most likely a pre-amp valve.

If you want to change amp valves always recommend changing the whole set while you are at. It only costs a little more and you know that everything is as it should be.

Click on the pictures to magnify

Thứ Tư, 9 tháng 8, 2017

Thứ Hai, 7 tháng 8, 2017

Chủ Nhật, 6 tháng 8, 2017

Samsung CS29A5HT8X/BWT - E2PROM (IC902) Replacement, service mode, memory data, white balance adjustment

Samsung CS29A5HT8X, CS29A5HT8X/NWT, CS29A5HT8X/VWT, CZ21A8VW8X/ELS

When IC902 is replaced, all adjustment data revert to the initial values. So, all adjustment values when servicing should be readjusted.After IC902 is replaced, connect the AC power supply cord.

Turn the power switch ON.

In stand-by, warm up the TV for at least 10 seconds.

Power on the TV.

White Balance Adjustment

Select STANDARD from the menu.

2. Input an 100% White pattern.

3. Enter the “Service Mode”. (Refer to “4-8 Service Mode”)

4. Warm up the TV set at least for 30 minutes.

5. Input a Toshiba pattern signal.

6. Enter the “Video Adjust1”.

* Adjust “Sub Contrast” so that Y (luminance) becomes 40 ft ± 3.

* Use “Red Drive” and “ Blue Drive” to adjust High-Light (x : 290, y : 300)

* Adjust “Sub Bright” so that Y (luminance) becomes 1.3ft ± 0.3.

* Use “Red Cutoff” and “Blue Cutoff” to adjust Low-Light (x : 290, y : 300).

7. Adjust CA-100 so that the final adjustment value can be fixed.

8. Use the Channel Up/Down (▲/▼) buttons to move the cursor on the adjustment modes.

9. Use the Volume +/- buttons to change the adjustment value.

Service Mode

To enter the “Service Mode”, Press the remote-control keys in this sequence:If you do not have Factory remote-control:

Use the Channel Up/Down buttons to move the cursor in the adjustment parameters.

* When CRT, CRT PCB, FBT, E2PROM (sometimes MICOM) is replaced, the adjustment values should be controlled.

* After the Service adjustment is completed, Do not select “Reset” in the service mode menu.

(After above procedure is done, power is on initially and the “Plug and Play” will be operated.)

Memory Data: (A) DEFLECTION (GEOMETRIC ADJUSTMENT VALUE)

Philips HTS3538 – SMPS and Power amplifier circuit diagram, software update, service mode

Philips Home Theater DVD Player HTS3538/12/51/55/05/98

Amplifier

Total output power: 600W RMS (30% THD)

Frequency response: 20 Hz-20 kHz / ±3 dB

Signal-to-noise ratio: > 65 dB (CCIR) /(A-weighted)

Input sensitivity: AUX: 2 V

Music iLink: 1 V

Total output power: 600W RMS (30% THD)

Frequency response: 20 Hz-20 kHz / ±3 dB

Signal-to-noise ratio: > 65 dB (CCIR) /(A-weighted)

Input sensitivity: AUX: 2 V

Music iLink: 1 V

Subwoofer

Output power: 100 W RMS (30% THD)

Impedance: 4 ohm

Speaker drivers: 133 mm (5.25") woofer

Dimensions (WxHxD): 160 x 267.5 x 265 mm

Weight: 2.55 kg

SpeakersOutput power: 100 W RMS (30% THD)

Impedance: 4 ohm

Speaker drivers: 133 mm (5.25") woofer

Dimensions (WxHxD): 160 x 267.5 x 265 mm

Weight: 2.55 kg

Center speaker:

Output power: 100 W RMS (30% THD)

Speaker impedance: 4 ohm

Speaker drivers: 1 x 63.5 mm (2.5") woofer

Dimensions (WxHxD): 160 x 85 x 95 mm

Weight: 0.37 kg

Front/Rear speaker:

Output power: 4 x 100 W RMS (30% THD)

Speaker impedance: 4 ohm

Speaker drivers: 1 x 76.2 mm (3") twin driver

Dimensions (WxHxD):

Speakers: 85 x 160 x 95mm

Tall speakers: 240 x 1007 x 240 mm

Weight:

Speakers: 0.35 kg/each

Tall speakers: 1.57 kg/each

Output power: 100 W RMS (30% THD)

Speaker impedance: 4 ohm

Speaker drivers: 1 x 63.5 mm (2.5") woofer

Dimensions (WxHxD): 160 x 85 x 95 mm

Weight: 0.37 kg

Front/Rear speaker:

Output power: 4 x 100 W RMS (30% THD)

Speaker impedance: 4 ohm

Speaker drivers: 1 x 76.2 mm (3") twin driver

Dimensions (WxHxD):

Speakers: 85 x 160 x 95mm

Tall speakers: 240 x 1007 x 240 mm

Weight:

Speakers: 0.35 kg/each

Tall speakers: 1.57 kg/each

Software upgrade method

1.Copy the bin file as "HTS3538_XX.bin".

2.Then use the file to burn the upgrade CD-R/CD-RW.

3.Put the CD in the tray ,let the player loading the disc.

4.If the CD is correct ,it will display the Upgrade Menu ,press the PLAY key on the remote control to start upgrade

5. Afer a while, the tray will open automatically ,but must not power off the player.

6.Don't power off ,wait until the player reset automatically ,the whole upgrade process may need 2 minutes .HTS will auto standby after complete upgrade.

if you upgrade with USB device

1. Step1 is same with DISC upgrade;

2.Copy the renamed bin file(upgrade file) to the root menu of USB device.

3.connect the USB device to HTS ,and switch to USB source;

4.The rest is same to step 4,step 5 and step 6 with DISC upgrade.

[The set must not be power off during upgrading; Otherwise the Main board will be damaged entirely.]

How to adjust the setting after repairing: [Service mode]

1 HTS3538/12: Open DVD tray, press “9” “9” “9” “9” “5” on R/C; 2” on R/C;

2 HTS3538/51: Open DVD tray, press “9” “9” “9” “9” “5” on R/C;

3 HTS3538/55: Open DVD tray, press “9” “9” “9” “9” “4” on R/C;

4 HTS3538/05: Open DVD tray, press “9” “9” “9” “9” “2” on R/C;

5 HTS3538/98: Open DVD tray, press “9” “9” “9” “9” “3” on R/C;

Restart after above steps.

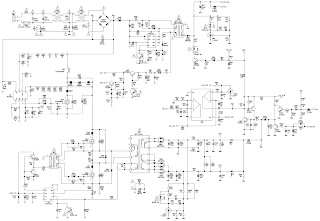

HTS3538 power amplifier schematic .

Power board [SMPS board] circuit diagram

Click on the schematics to zoom in

Thứ Sáu, 7 tháng 7, 2017

Samsung CS21M16MJZXNWT CRT TV – how to enter the service mode, circuit diagram

High Voltage Limits

High voltage must be measured each time servicing is done on the B+, horizontal deflection or high voltage circuits. Correct operation of the X-ray protection circuits must be reconfirmed whenever they are serviced.

(X-ray protection circuits also may be called “horizontal disable” or “hold-down”.)

Proceed the high voltage limits. These include the X–ray Protection Specifications Label, and the Product Safety and X-ray Warning Note on the service data schematic.

[The CRT is charged with high voltage. Before removing the Anode Cap, discharge the voltage through one of the heat sinks on the main board.]

1. Do not attempt these adjustments in the Video Mode.

2. The Factory Mode adjustments are necessary when either the EEPROM (IC902) or the CRT is replaced.

3. Do not tamper with the “Adjustment” screen of the Factory Mode menu. This screen is intended only for factory use.

When EEPROM (IC902) Is Replaced

1. When IC902 is replaced all adjustment data revert to initial values. It is necessary to re-program this data.

2. After IC902 is replaced, warm up the TV for 10 seconds.

Factory/Service Mode (This mode uses the standard remote control.)

1.The Service Mode is activated by entering the following remote-control sequence:

(1) DISPLAY=>FACTORY.

(2) STAND-BY=> DISPLAY=> MENU=> MUTE =>POWER ON.

2. The “SERVICE (FACTORY)” message will be displayed. The Service Mode has three components: ADJUST, OPTION,OPTION1,G2 Adjust and Reset.

3. Access the Adjustment Mode by pressing the “VOLUME” keys ( Up or Down). and selected by pressing the CHANNEL keys (▲ ,▼).

4. Selection sequences for the all system:

DOWN or UP key

AGC>SCT>SBT>BLR>BLB>RG>GG>BG> VSL>VS>VA>HS>SC>CDL>STT>AKB> PDL>NDL>PSR>NSR>VOL>LCO>TXP> FMVOL>FMWS>AGCS>OMD>SCL>PWL> AGN>PEK>ACL>FCO>SCBT>SSP>PSNS

5. The VOLUME keys increase or decrease the adjustment values (stored in the non-volatile memory) when Adjustment Mode is cancelled.

6. Cancel the Adjustment Mode by re-pressing the “FACTORY” or “Power OFF” keys.

Cathode voltage adjustment 9Screen voltage)

Input a gray scale pattern.

( Use a pattern generator,PM5518)

2. Enter "Adjustment" Mode:

3. Select "G2 adjust" by pressing channel key Up/Dn.

4. Enter "G2 adjust" by pressing channel key Left/Right

5. Adjust he screen Vr (On the FBT),so that OSD becomes "SCREEN ADJEST:OK"

High voltage must be measured each time servicing is done on the B+, horizontal deflection or high voltage circuits. Correct operation of the X-ray protection circuits must be reconfirmed whenever they are serviced.

(X-ray protection circuits also may be called “horizontal disable” or “hold-down”.)

Proceed the high voltage limits. These include the X–ray Protection Specifications Label, and the Product Safety and X-ray Warning Note on the service data schematic.

[The CRT is charged with high voltage. Before removing the Anode Cap, discharge the voltage through one of the heat sinks on the main board.]

Power, CRT, Vertical and Horizontal section schematic

Onechip and MICOM

Sound and External AV

Factory Mode1. Do not attempt these adjustments in the Video Mode.

2. The Factory Mode adjustments are necessary when either the EEPROM (IC902) or the CRT is replaced.

3. Do not tamper with the “Adjustment” screen of the Factory Mode menu. This screen is intended only for factory use.

When EEPROM (IC902) Is Replaced

1. When IC902 is replaced all adjustment data revert to initial values. It is necessary to re-program this data.

2. After IC902 is replaced, warm up the TV for 10 seconds.

Factory/Service Mode (This mode uses the standard remote control.)

1.The Service Mode is activated by entering the following remote-control sequence:

(1) DISPLAY=>FACTORY.

(2) STAND-BY=> DISPLAY=> MENU=> MUTE =>POWER ON.

2. The “SERVICE (FACTORY)” message will be displayed. The Service Mode has three components: ADJUST, OPTION,OPTION1,G2 Adjust and Reset.

3. Access the Adjustment Mode by pressing the “VOLUME” keys ( Up or Down). and selected by pressing the CHANNEL keys (▲ ,▼).

4. Selection sequences for the all system:

DOWN or UP key

AGC>SCT>SBT>BLR>BLB>RG>GG>BG> VSL>VS>VA>HS>SC>CDL>STT>AKB> PDL>NDL>PSR>NSR>VOL>LCO>TXP> FMVOL>FMWS>AGCS>OMD>SCL>PWL> AGN>PEK>ACL>FCO>SCBT>SSP>PSNS

5. The VOLUME keys increase or decrease the adjustment values (stored in the non-volatile memory) when Adjustment Mode is cancelled.

6. Cancel the Adjustment Mode by re-pressing the “FACTORY” or “Power OFF” keys.

Cathode voltage adjustment 9Screen voltage)

Input a gray scale pattern.

( Use a pattern generator,PM5518)

2. Enter "Adjustment" Mode:

3. Select "G2 adjust" by pressing channel key Up/Dn.

4. Enter "G2 adjust" by pressing channel key Left/Right

5. Adjust he screen Vr (On the FBT),so that OSD becomes "SCREEN ADJEST:OK"

Thứ Ba, 27 tháng 6, 2017

Akira 14THS3/CE CTV UOC OM8370 or TDA9381- Service mode - schematic – fault finding

How to enter service mode – Akira 14THS3, 14 inch color TV, Troubleshooting, circuit diagram, working principle

The high voltage in the TV reaches to 22KV when the TV is in operation. Be more careful during opening the back cover. The high voltage existing in the TV is very dangerous. Refer servicing to qualified personnel only.SIGNAL PROCESS

The TV signal enters into tuner (A201) from cable or antenna. Pin 10 and pin 11 of N301 are combined to select the band. Pin 4 of N301 outputs PWM tuning signal. The 38.9MHz IF signal is coupled to V308 (pre-amplify) and then to SAWF (Z301). After processed in the SAWF, the 38.9MHz signal gets to pin 23 and pin 24 of OM8370. The IF circuit in OM8370 includes such unit as the AGC amplifying circuit, 38.9MHz oscillator, PLL video demodulator, video amplifier, IF identify circuit and AFT circuit. The demodulated signal (CVBS) comes from the pin 38 of OM8370, the sound signal comes from the pin 44.

The internal CVBS signal needs norm identification then outputs from pin 38 of OM8370, via the trap circuit (composed of the V351, Z351, Z354, V352 and so on) feeds back to the pin 40 of OM8370. The RGB signal comes from pin51, Pin52, Pin53 of OM8370, and outputs to the CRT board. The internal sound signal comes from pin 44 of OM8370 and then input to pin 1 and pin 12 of HEF4052BP. The sound signals from RF and AV are selected in it. The selected signal is output from Pin 3 and pin13, then input AN7522N (sound amplifier) or output from AV terminals.

HORIZONTAL AND VERTICAL CIRCUIT

Through Synchronous separating circuit, the video signal is divided into horizontal-Synchronizing signal and Vertical-Synchronizing signal. The horizontal-Sync pulse coming from pin 33 is transferred to the horizontal-drive transistor. The cathode driving voltage 180V vertical drive voltage +15V and –15V are all generated from

FBT. The vertical sawtooth waveform is generated on the pin 21 and 22, and then enters the vertical amplifier STV9302A. STV9302A is a 7 pins vertical deflection circuit (2 Amperes) for DC-coupled 90° or 110° deflection systems with frame frequencies from 50 up to 120 Hz. one supply voltage for the scanning and second voltage supply for the flyback are needed. The vertical drive currents of OM8370 pins 21 and 22 are connected to input pins 1 and 7 of STV9302A. The vertical scanning output is coming from pin 5 and feed back to pin 1 by R405. The supply voltage is ±15V at pin 2 and pin 4. C406 is the pump capacitor.

Through Synchronous separating circuit, the video signal is divided into horizontal-Synchronizing signal and Vertical-Synchronizing signal. The horizontal-Sync pulse coming from pin 33 is transferred to the horizontal-drive transistor. The cathode driving voltage 180V vertical drive voltage +15V and –15V are all generated from

FBT. The vertical sawtooth waveform is generated on the pin 21 and 22, and then enters the vertical amplifier STV9302A. STV9302A is a 7 pins vertical deflection circuit (2 Amperes) for DC-coupled 90° or 110° deflection systems with frame frequencies from 50 up to 120 Hz. one supply voltage for the scanning and second voltage supply for the flyback are needed. The vertical drive currents of OM8370 pins 21 and 22 are connected to input pins 1 and 7 of STV9302A. The vertical scanning output is coming from pin 5 and feed back to pin 1 by R405. The supply voltage is ±15V at pin 2 and pin 4. C406 is the pump capacitor.

POWER SUPPLY

The IC of KA5Q0765RT is adapted in this chassis; it is the product of Fairchild. It supplies four DC voltages, one is the +B=110V, another is Hcc=26V, the third is 13V (the sound drive voltage), the fourth is +16V. The +16V can generate the +8V, +5V and +3.3V by the special generators.

The IC of KA5Q0765RT is adapted in this chassis; it is the product of Fairchild. It supplies four DC voltages, one is the +B=110V, another is Hcc=26V, the third is 13V (the sound drive voltage), the fourth is +16V. The +16V can generate the +8V, +5V and +3.3V by the special generators.

FACTORY MENU / Service mode

Main power +B setting

Receive standard color pattern RF signal. Set picture to “Standard Mode”. Adjust VR501, to get +B (VD542 -) voltage =110V.

I2C bus control adjustment method

How to enter and exit factory mode (with customer’s remote controller)

1. Press [menu] key > display picture menu

2. Press digital key “6” “4” “8” “3” - display “M”

3. Push [standby] key one time to exit factory mode and return to normal.

How to select menus in factory mode

In factory mode {“M” mode} there are ten menus totally. Menu 1 to Menu 4 can be selected directly but Menu 5 to Menu 0 must be select by these steps:

1. Press “CALL” key, to call “M”.

2. Press “LOCK” key, then press any one numeric key from 5 to 0.

For example, to select Menu 7, you should press “call” key and LOCK key in turns, then press the numeric key 7

Main power +B setting

Receive standard color pattern RF signal. Set picture to “Standard Mode”. Adjust VR501, to get +B (VD542 -) voltage =110V.

I2C bus control adjustment method

How to enter and exit factory mode (with customer’s remote controller)

1. Press [menu] key > display picture menu

2. Press digital key “6” “4” “8” “3” - display “M”

3. Push [standby] key one time to exit factory mode and return to normal.

How to select menus in factory mode

In factory mode {“M” mode} there are ten menus totally. Menu 1 to Menu 4 can be selected directly but Menu 5 to Menu 0 must be select by these steps:

1. Press “CALL” key, to call “M”.

2. Press “LOCK” key, then press any one numeric key from 5 to 0.

For example, to select Menu 7, you should press “call” key and LOCK key in turns, then press the numeric key 7

Troubleshooting

No OSD (On Screen Display)

This failure is usually cause by the circuit of character generated and located. Most of reasons are that the horizontal and vertical flyback pulse signals do not come to UOC. We can judge this failure by measuring the wave of the character in an oscilloscope. The detail checking and repairing steps are as follow:

This failure is usually cause by the circuit of character generated and located. Most of reasons are that the horizontal and vertical flyback pulse signals do not come to UOC. We can judge this failure by measuring the wave of the character in an oscilloscope. The detail checking and repairing steps are as follow:

Click on the pictures to zoom in

UOC does not work

In television, remote-control system is similar with the computer system. In theory , it can work if it holds two conditions as follow:

1) The power supply: In general, it is 5V, the error is not above 10% and the disturbance pulse is as small as possible.

2) The clock pulse: In TDA93XX circuit, the clock pulse is generated by pin58 / pin59 of N301 and 12M crystal oscillator.

Television’ s remote-control system also needs reset circuit that can preset the values in internal register. The circuit around pin57 of N204 is called auto-reset circuit. If UOC detects errors in resetting, it will come to the state of program protected.

In television, remote-control system is similar with the computer system. In theory , it can work if it holds two conditions as follow:

1) The power supply: In general, it is 5V, the error is not above 10% and the disturbance pulse is as small as possible.

2) The clock pulse: In TDA93XX circuit, the clock pulse is generated by pin58 / pin59 of N301 and 12M crystal oscillator.

Television’ s remote-control system also needs reset circuit that can preset the values in internal register. The circuit around pin57 of N204 is called auto-reset circuit. If UOC detects errors in resetting, it will come to the state of program protected.

Schematic

No raster, no picture, no sound

This failure is mainly caused by big-power circuit such as power supply, horizontal scanning, vertical scanning. The detail checking and repairing steps are as follow.

This failure is mainly caused by big-power circuit such as power supply, horizontal scanning, vertical scanning. The detail checking and repairing steps are as follow.

No picture, no sound

The failure shows that the set does not display the picture but it has noise wave or blue background or OSD on the screen. This means that the circuits of power supply, horizontal scanning, vertical scanning and video amplification are normal and they are not considered in the repairing. The failures are mainly in the small signal processing circuits.

Before checking these circuits, a kind of practical test method is introduced. It is called “Signal-input way ”. The detail is described as follow: We can use the resistance function of an analog multimeter, connect the red pole (negative in ohm scope) on the circuit board ground, then touch softly the test point with another pole (black pole) in ohm scope meanwhile observe the reactivity on the output device.

Note : In the TV test, we mainly observe the noise wave on the CRT and listen to the noise voice liking as “Ka…..Ka” from the loudspeakers.

No sound

In this kind of failure, first of all we should observe if there is the picture on the CRT. It proves the small signal circuit to work correctly with the picture on the CRT and we only check the sound signal processing and sound amplification circuit. The repairing method(B1) may be referred without picture. The detail checking and repairing steps are as follow.

Note: Before repairing, assure that the volume is on and the state of set is in “TV”

In this kind of failure, first of all we should observe if there is the picture on the CRT. It proves the small signal circuit to work correctly with the picture on the CRT and we only check the sound signal processing and sound amplification circuit. The repairing method(B1) may be referred without picture. The detail checking and repairing steps are as follow.

Note: Before repairing, assure that the volume is on and the state of set is in “TV”

Only horizontal line in the middle of the screen

If vertical deflection circuit does not work, this kind of failure will happen. In deflection yoke, there only has horizontal sweep, the electron beam in the CRT only moves in the horizontal orientation , so form this failure. (While checking horizontal and vertical deflection circuit’ s failure , we have better to use an oscilloscope.)

If vertical deflection circuit does not work, this kind of failure will happen. In deflection yoke, there only has horizontal sweep, the electron beam in the CRT only moves in the horizontal orientation , so form this failure. (While checking horizontal and vertical deflection circuit’ s failure , we have better to use an oscilloscope.)

Only vertical line in the middle of the screen

This is a dangerous failure. It probable causes flashover and smoking inside the set. Don’ t let your TV work for a long time as this failure appears. Because the electron beam can not move in the horizontal orientation, the failure should be in the horizontal deflection circuit. We mainly check the open-circuit fault in horizontal deflection circuit. The detail checking and repairing steps are as follow

This is a dangerous failure. It probable causes flashover and smoking inside the set. Don’ t let your TV work for a long time as this failure appears. Because the electron beam can not move in the horizontal orientation, the failure should be in the horizontal deflection circuit. We mainly check the open-circuit fault in horizontal deflection circuit. The detail checking and repairing steps are as follow

OM8370/TDA9340 pin functions

Philips 40PFG5100-77 LED LCD TV –SMPS circuit diagram, Pin voltages - Chassis TPM15.4L

Philips 32PFG5100, Philips 40PFG5100 and Philips 48PFG5100 - SMPS and Back-light inverter schematic - Power Supply Unit A715G6934 Schematic and connector voltages.

All power supplies are a black box for Service. When defective, a new board must be ordered and the defective one must be returned, unless the main fuse of the board is broken. Always replace a defective fuse with one with the correct specifications. This part is available in the regular market.Consult the Philips Service web portal for the order codes of the boards.

Important delta’s with the TPM15.4L LA chassis platform are:

* New power architecture for LED back-light

* “Boost”-signal is now a PWM-signal + continuous variable.

The control signals are:

> Stand-by

> Lamp “on/off”

> Backlight adjust (DIM) (not for PSDL)

In this manual, no detailed information is available because of design protection issues.

The output voltages to the chassis are:

> +8.5V output (standby)

> +12V (on-mode)

> +12V_audio (audio AMP power)

> Output to the display; in case of

* IPB: High voltage to the LCD panel

* PSL and PSLS (LED-driver outputs)

* PSDL (high frequent) AC-current.

Diversity

The diversity in power supply units is mainly determined by the diversity in displays.

The following displays can be distinguished:

> CCFL/EEFL backlight: power panel is conventional IPB

> LED backlight:

* side-view LED without scanning: PSL power panel

* side-view LED with scanning: PSLS power panel

* direct-view LED without 2D-dimming: PSL power panel

* direct-view LED with 2D-dimming: PSDL power panel.

PSL stands for Power Supply with integrated LED-drivers.

PSLS stands for a Power Supply with integrated LED-drivers with added Scanning functionality (added micro-controller).

PSDL stands for a Power Supply for Direct-view LED back-light with 2D-dimming.

> CCFL/EEFL backlight: power panel is conventional IPB

> LED backlight:

* side-view LED without scanning: PSL power panel

* side-view LED with scanning: PSLS power panel

* direct-view LED without 2D-dimming: PSL power panel

* direct-view LED with 2D-dimming: PSDL power panel.

PSL stands for Power Supply with integrated LED-drivers.

PSLS stands for a Power Supply with integrated LED-drivers with added Scanning functionality (added micro-controller).

PSDL stands for a Power Supply for Direct-view LED back-light with 2D-dimming.

Connector voltages

DC/DC Converters

The on-board DC/DC converters deliver the following voltages (depending on set execution):

* +5V-STANDBY, permanent voltage for the Stand-by controller, LED/IR receiver and controls.

* +12V, input from the power supply for the panel common(active mode)

* +12V, input from the power supply for the AMP

* +1V2, from the power supply for the scaler IC MT5580

* +1V5, supply voltage for DDR2 ( diagram B03B)

* +3V3, general supply voltage.

* +3V3-TUN, supply voltage for tuner

* +5V-USB, input intermediate supply voltage for the USB Power

* +3V3, from the power supply for the scaler IC MT5580

* +3V3-DVBS, clean voltage for Demodulator IC channel decoder

A715G6550 SMPS circuit diagram [Schematic]

LED Driver schematic

Click on the schematics to magnify

Chủ Nhật, 18 tháng 6, 2017

DPS 186CP-1 Universal LCD TV Power board Circuit diagram circuit description and troubleshooting

Used with - Haier P32R1, Haier L32F1, Haier LK32K1, Haier L32R3and Vizio VOJ320F1A

Haier L32Fl LCD TV power supply voltage is + 5V, +12 V and +24 V three groups, of which 5V for the standby power, to the motherboard standby circuit power supply, 12V to the motherboard power supply, 24V to the back-light board power supply.Standby circuit start process

Power board connected to the mains, 220V by C6, LF2, VR1, C3, C5, C4, LF1, Ll filter, and then by BD1 rectifier, Cl filter, get +103 V DC, divided into two by Tl and T3 transformer primary added to the V2 "D" pole, standby power supply chip U3 (NCP1014AP65G) (5) feet. Leaving aside the main power circuit for the time being, say U3 Standby power chip, U3 (5) feet after the power, the chip built-in boot circuit first to E6 charge, when the E6 voltage rises to About 7.5V. U3 internal oscillation circuit began to oscillate into the working state, U3 work after the T3 transformer primary auxiliary Winding generation of 12V, 15V two groups of DC voltage. 12V for the U3 work to provide secondary power supply, to maintain oscillation; 15V then three poles Tube V9 (C1008) c pole. V9 controlled by the on / off control circuit to achieve the main power supply Ul power supply control. T3 transformer secondary Produce + 5V / 0.7A voltage to the motherboard control circuit (key processing, remote control signal processing, on / off processing circuit J for Electricity. D8, C27, R40 for the spike absorption circuit, inhibit the switch in the off when the peak pulse generated damage U3 Switch tube.

5V standby voltage regulator

+ 5V voltage by R115, R116 divided to U7 (TL431) (1) pin reference voltage input, through the internal circuit Control voltage output. U7 is characterized by (1) pin voltage rise, (3) pin voltage drop. U1 (4) pin voltage is controlled by Ul0, Adjust the chip built-in PWM generator duty cycle, forcing the secondary output voltage stability.

Main power circuit start process

When the motherboard receives the power on signal, the motherboard output on / off control voltage (+5 V) by CON3 connector (7) Feet added to the V11 (9014) b pole, so that the c-pole potential pulled low, U9 (PC817) optocoupler power conduction, 15V by R30, U9 secondary To V9 (C1008) b pole, so that V9 conduction. V9 e output + 12V voltage by V4, R13 added to the Ul (6) feet. U8 (TL431), D4, Dll (ER106), R21, R22, R31, R52, R51 and other components of the mains voltage detection circuit, under normal circumstances, V4 Was turned on. AC 220V voltage is too low, U8 trigger pin (1) pin voltage drop, U8 cut off so that V4 to stop working, No vCC for Ul work, the machine was standby state. Ul (NCP1377B) main power chip (6) feet get 12V operating voltage , The internal oscillator starts to work, the (5) pin output PWM signal added to the control of V2, so that V2 work in high-frequency open Off state. In the Tl to produce a change in the pulse voltage, Tl primary pulse voltage generated in the T1 secondary induced voltage by D12, D14, D19 (ST20N150) fast recovery diode rectifier, the E7, E8, E9, C8, El0 filter to get +24 V / 6A power Pressure. The U2 (LM34167) circuit is a DC-DC converter that converts the + 24V voltage to + 12V / 3A, E14 filter output.

Click on the pictures to zoom in

Main power circuit regulator process

R91, R86, R87 components of the partial pressure sampling circuit, when the +24 V voltage increases, the partial pressure sent to U5 (TL431) (1) feet, U5 (3) pin voltage becomes low, U11 (PC817) optocoupler conduction, the Ul (NCP1377B) main power chip (2) the pin potential is pulled low, the power chip output PWM duty cycle decreases. V2 (MOS) tube conduction time becomes shorter, so that the transformer The secondary voltage is reduced to complete the regulator process. +2 4V voltage regulator when the voltage regulator circuit with the above process is the opposite process.

Main power over-current detection circuit

When a cause causes the current in the V2 MOS tube to increase. R60, R61 resistance on the pressure drop also increased The voltage is supplied to the Ul (3) pin current detection via R20 when the (3) pin voltage rises to the chip threshold voltage. Ul main power chip stop Vibration, thus avoiding V2 over-current damage.

Main power over-voltage detection circuit

When some cause caused +103 V voltage rise, Tl transformer (7) feet induced voltage is also increased, R3 The voltage will rise, when the voltage of R3 to the chip (1) internal set value, the over-voltage protection circuit action, Ul stop vibration.

How to determine if the fault is on the power board.

The power board can be removed from the machine, so repair more convenient. Place the power supply board face up and place it on an insulated desk. Be sure to pay attention to insulation. Use a wire to shorten the + 5v with the CON3 connector ⑦ pin (ON / OFF) to start the power supply.

After receiving the dummy load, use a multimeter to detect + 5V (CON4 connector (1) a (2) feet), + 12V (CON3 (2) a (5) feet), +24 V (CON2 connector (3) a (8) feet) voltage is normal, such as the three groups of voltage is not normal, Can determine the fault in the power board, otherwise the other circuit failure.

(1) false load general power board secondary output socket are marked with the current value of each group of voltage, according to this current

Value to calculate the load resistance value easily. Such as: 12V / 3A-4Ω / 36W. For easy maintenance, with lOkΩ resistor with oneOnly LED series connected to the dummy load, can be intuitive to indicate the power of each group of voltage work.

(2) Note that the best power with a switch with the socket, first connect the power cord, and then press the switch, do not leave the first hand.

Such as lOs after the elements do not smoke, burst and other abnormalities can be detected.

Power board power, El ends are still about 30V high pressure, please use PTC before the maintenance (positive temperature coefficient Thermistor J is its discharge.

(3) "three noes" maintenance process "three no" fault most of the power board failure, this time do not blindly power detection, Should first "look", see the power board rectifier bridge, +103 V filter capacitor, MOS tube, switching power supply chip and other large power components Whether the surface is black, charred, burst and other anomalies, so that you can quickly find the fault area, reduce the fault detection range, But also to prevent blind power caused by the failure to expand again, causing security risks. If no anomalies are found, they can be energized and measured + 5V (CON4 connector (1) feet) voltage is normal, such as voltage is not normal or no voltage, then the standby power supply circuit work abnormal. At this time can be measured in turn + 310V (El ends) voltage, standby power supply chip power supply VCC + 7.8V (E6) voltage, And determine whether ZD3, U3, T3, R6, R42, L2, etc. are faulty.

(4) +5 V voltage is not normal maintenance process + 5V voltage is low or unstable is generally sampling feedback circuit, power chip vibration And drive circuit failure. Can detect standby power supply chip VCC + 7.8V (E6) voltage, if the voltage is normal, then Can determine the fault in the sampling feedback circuit. Such as abnormal main detection of the power chip itself or power chip oscillation and drive the electricity

(5) + 5V normal, do not boot maintenance process without +12 V, +24 V voltage.

Fault range is relatively large, there are on / off circuit, the main power oscillation circuit, the main power supply sampling feedback circuit.

Maintenance should first test CON3 connector (7) feet whether the 5V boot voltage, if not, then the fault in the motherboard standby power Road, such as normal can be carried out in accordance with the following steps to repair.

It is to be noted that the power supply board is made of R21, R22, R31, R51, R52, U8, R33, V4, R13 and other components of the mains detection circuit, such as the above components are open or bad, will lead to +15 V on / off voltage cannot be smooth To the Ul (NCP1377B) main power chip (6), so that the main power supply can not start. + 12V and + 24V are no output. Such as arms Suspected of this circuit is faulty, can V4 (9012) c-e very short, such as the normal power supply to start, that failure in the circuit, such as still not See the power to start, indicating fault in other circuits

(6) no +12 V voltage output maintenance process +12 V DC-DC circuit is relatively simple, generally U2 (LM34167) Bad, overhaul can be changed, such as can not rule out the fault, you can check L4, R82, R83, R84 and other components.

Thứ Năm, 15 tháng 6, 2017

How to enter the SERVICE mode China TV kit using TDA9374 System-Chroma jungle – PF2939 chassis - Circuit diagram

Used semiconductors and transformers

STR-F6454R (SMPS control), TDA9384, TDA8360Q, TDA9859, TDA7057AQ, TA75558P, TDA7056B, TDA6107Q, HEF4053BP, AT24C08(Memory), TDQ-5B6M(Tuner), BSC68Z (FBT)

How to enter the service mode

Set the volume to 0 by the remote control. Then press and hold the MUTE button on the remote control and MENU button on the TV at the same time for over 2 seconds. In the S mode, press the POWER button to quit the S mode.

Use the Dn/Upbuttons on the remote control to highlight an adjustment and the L/R buttons

to adjust it.

The POS +/-,UP/DN,L/R, 1~6, RECALL, VOL+/-, MUTE and POWER buttons on the remote control function in the S mode, but 100+, 7, 8, 9 and 0 buttons not.

Schematic

STR-F6454R (SMPS control), TDA9384, TDA8360Q, TDA9859, TDA7057AQ, TA75558P, TDA7056B, TDA6107Q, HEF4053BP, AT24C08(Memory), TDQ-5B6M(Tuner), BSC68Z (FBT)

How to enter the service mode

Set the volume to 0 by the remote control. Then press and hold the MUTE button on the remote control and MENU button on the TV at the same time for over 2 seconds. In the S mode, press the POWER button to quit the S mode.

Use the Dn/Upbuttons on the remote control to highlight an adjustment and the L/R buttons

to adjust it.

The POS +/-,UP/DN,L/R, 1~6, RECALL, VOL+/-, MUTE and POWER buttons on the remote control function in the S mode, but 100+, 7, 8, 9 and 0 buttons not.

Schematic

Click on the schematics to magnify

Đăng ký:

Bài đăng (Atom)